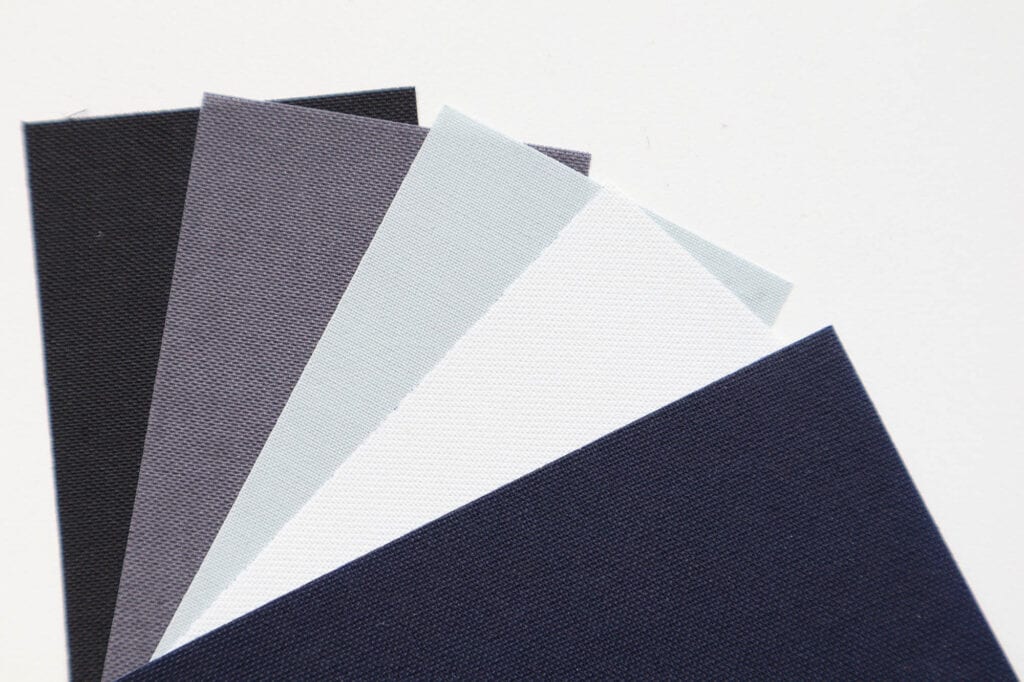

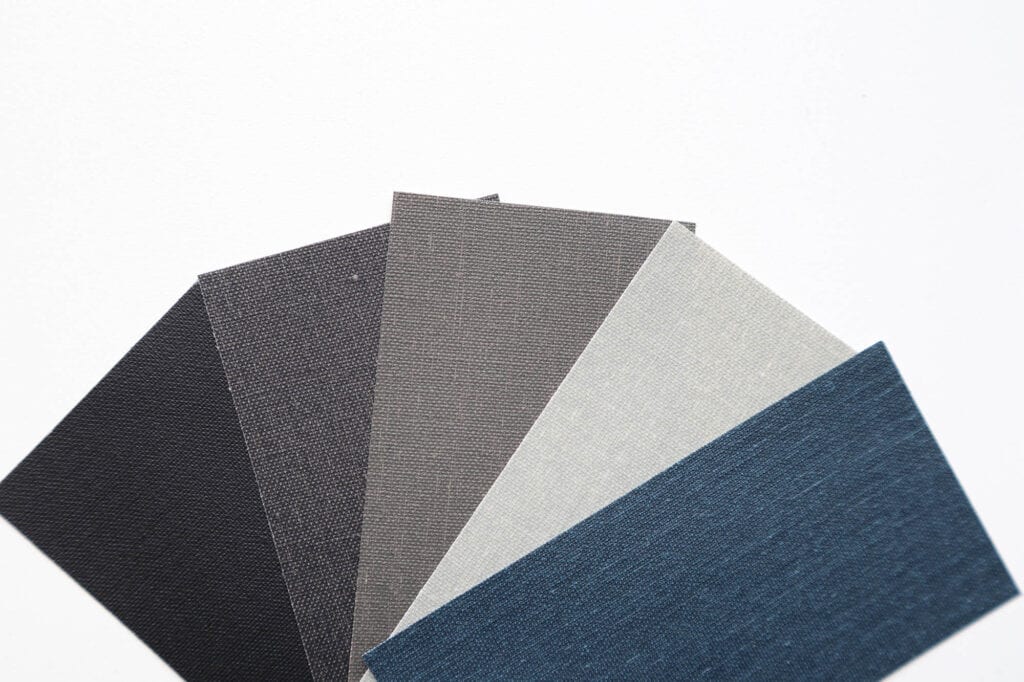

Designing a book is one of my favorite things to do. I like choosing the paper, board and ribbon, but I absolutely love picking out the cover material. Book covers are meant to protect and reflect the content inside, so it’s important to choose materials that serve both purposes well. Book cloth is a natural choice, because it’s specifically created to resist staining, dirt, oils and water. Here’s the kicker, though – not all book cloth is created equal. Some are weak in strength, but high in beauty. Others are extremely durable, but lack flexibility and finish.

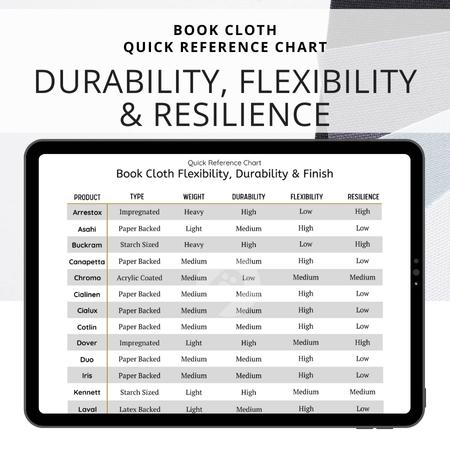

In this post, I’ll show you how to choose book cloth for your project by explaining how the manufacturing process impacts the performance, durability and finish of different cloths. At the end, I’ve added a Quick Reference Chart: Book Cloth Durability, Flexibility & Resilience to make it easy for you to find the right cloth for your project.

As you read through this post, consider what your book will be used for and how it will be handled. Books that will receive a lot of handling should have a strong cloth whereas fine bindings and art pieces can tolerate natural fabrics with less treatment.

Quick history

Book cloth has a long history going back hundreds of years, but it wasn’t specifically manufactured for book binding until the 19th century. At the time, book demand was at an all-time high. Makers needed to find a widely available, inexpensive material to enable high production. Cotton became the go-to raw material because it was easy to process and took chemical processes (bleaching and starching, among others) well.

At first, cotton bindings were considered crude. The material was very thin and the process of starch sizing (where the surface was treated with starch to stop glue from soaking through) left visible blemishes on the surface. Over time, the manufacturing process improved to correct these faults.

Today, book cloth is still processed using many of the original methods, but advances in technology have given us more form and function combinations than ever before.

Book cloth vs. regular fabric

Book cloth is preferred to “just any fabric” because it has been manufactured using processes designed to help it resist staining, dirt, oils and to maintain archival qualities (acid-free, pH neutral). Apart from these dangers, a book’s greatest adversary is water. Since water and paper don’t play well together, book cloth is often treated to help protect against aqueous invasion (lol). This treatment may be chemical or added layers of defense.

Sizing

“Sizing” refers to a process of injecting filler into the cloth to close the gaps between the fibers. Closing up these gaps prevents water from getting through and adds strength, but can change the final appearance. There are two primary types of sizing to be aware of: starch sizing and impregnated sizing.

Starch sizing

Starch is one of the oldest additives to be used in book cloth manufacturing. It’s still used today, though the process has been refined and improved over time.

To create the starch, a mixture of water, starch, clay and pigment is drawn up and reduced down to a thick, dough-like consistency. The mixture is then spread across the face of the cloth using large spreading knives to ensure it’s thinly laid. The entire piece is then dried and pressed through heat rollers.

- Examples of starch sized cloths include: Buckram, Kennett, Euro Library Buckram

Impregnated sizing

In impregnated sizing, synthetic materials such as latex or acrylic replace starch. Impregnated cloths typically have a very different look and feel to them than their starched cousins. Depending on the filler, they may also be odor-free and mildew resistant.

The processes of starching and impregnating greatly increase a cloth’s durability and resistance to wear over time.

- Examples of impregnated cloths include: Dover, Arrestox

Paper & Latex backing

Backing cloth with a layer of paper (tissue, washi, etc.) or latex creates a barrier between the glued surface and the cloth itself, preventing water from seeping through. Since paper backed cloth does not contain any filler, the original look, feel and finish of the fabric is maintained.The paper itself is easy to markup and work with, making it ideal for many uses and new book binders.

Paper backing isn’t as durable as sized cloth, but it gives us a lot more options in terms of the overall look and feel.

- Examples of paper backed cloths include: Asahi, Cialinen, Canapetta, Cialux, Cotlin, Duo, Iris

- Examples of latex backed cloths include: Laval Flocked

Acrylic coated book cloth

Acrylic coated book cloth is fairly new. Instead of sizing the cloth with filler, acrylic is used to coat the surface. This adds water resistance and allows for flexibility while maintaining the original look of the fabric. The acrylic also gives the cloth a smooth, shiny surface.

- Examples of acrylic coated book cloths include: Chromo, Euro Library Buckram (lacquered coating)

Where to find book cloth

Here are a few retailers with a selection of book cloths. I’ve personally used Talas Online and Hollander’s, but cannot speak for the others.

Book cloth quick reference chart

I created a neat chart to compare all of these book cloth features at-a-glance. It’s extremely handy when I’m ordering cloth online or over the phone for a project. If you want to grab a copy, click the image below and I’ll send it over.

More bookbinding goodness

✨ What tools do I need to get started bookbinding?

- Bookbinding Tools & Supplies Quick Start Guide – learn all about book making tools, which to buy first & where to go online

- Pick up my popular Complete Starter Bookbinding Tools Kit – all the bookbinding essentials in one spot

🌟 Looking for a simple way to start making books?

Try a Complete Book Materials Kit. Each one has everything you need (+ tutorials & videos) to make a beautiful book without all the fuss.

Thank you for taking me along on your book making journey!

Misty