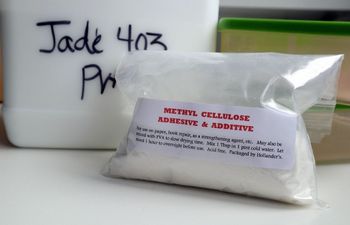

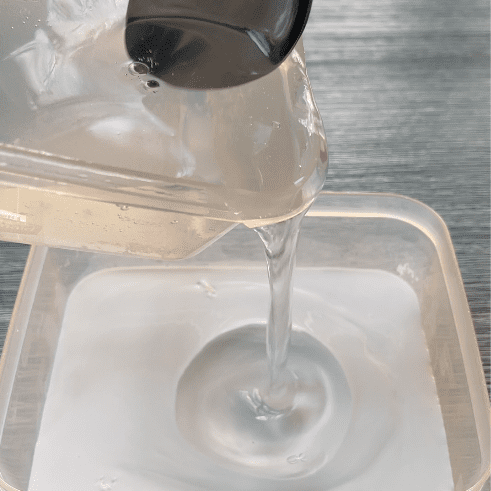

By itself, PVA (polyvinyl acetate) is an awesome glue for most bookbinding projects because it goes on thick, dries quickly and remains clear and flexible. For some jobs, though, it’s nice to have a longer dry time or a thinner adhesive that won’t tear delicate paper during application. In these moments, it might make more sense to use pva mixed with methyl cellulose.

Methyl Cellulose is a gel-like substance derived from plants, so it’s non-toxic and safe to mix with standard PVAs. This post assumes you have a base understanding of methyl cellulose (you can learn how to make and mix Methyl Cellulose with PVA here), so we’re going to focus on the best way to use PVA mixed with methyl cellulose in regular bookbinding projects.

When does it make sense to use PVA mixed with Methyl Cellulose over standard PVA?

This is a great question with a not-so-great answer: it depends.

But wait! I’m not the kind of person to leave you hanging with that semi-frustrating response, so I ran a series of experiments.

My goal was to understand which papers work best with standard PVA vs. PVA mixed with methyl cellulose. I chose to test on paper because it’s most common, but this whole process could be repeated on other materials like book cloth, synthetic or natural animal hides, etc.

Pros and Cons of mixing PVA + Methyl Cellulose

As with all things in life, there are pros and cons to consider before you use PVA mixed with methyl cellulose. Here are a few of each (specific to bookbinding).

Pros (benefits)

- Thins PVA, making it easier to control how much is applied

- Lubricates PVA, making it easier to apply without damaging paper

- Extends dry time, leaving more room to reposition

Cons (downsides)

- Reduced shelf life to 2 months (standard PVA has a shelf life of 2 years, but this is reduced to 2 months when mixed with methyl cellulose)

- May be too thin for highly porous materials

- Extended dry time means it will take longer to complete a project

Understanding the pros and cons is great, but when does it make sense to use standard PVA over a blend? Well, that’s exactly what I’m trying to figure out.

Enter: the experiment.

The Experiment

Disclaimer: I’m not a trained scientist. This test wasn’t formal by any means and I’m sure there are more precise methods, but I think it gives us everyday people a general idea of what works and what doesn’t.

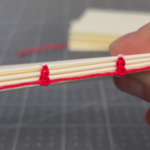

The goal of this experiment is to gauge how each adhesive (either standard PVA or PVA mixed with methyl cellulose) performs across various thicknesses of paper. Why? Well, most bookbinders use some form of paper covering for their projects (I wrote about my personal favorites here), so it seems like a good place to start.

When I say “performs,” I’m referring to the following:

- Ease of application (how easy it is to spread the glue without damaging the paper)

- Set time (how much time I have to move the paper around before it bonds)

Now that we have a goal and some markers, let’s get down to business.

Testing Process

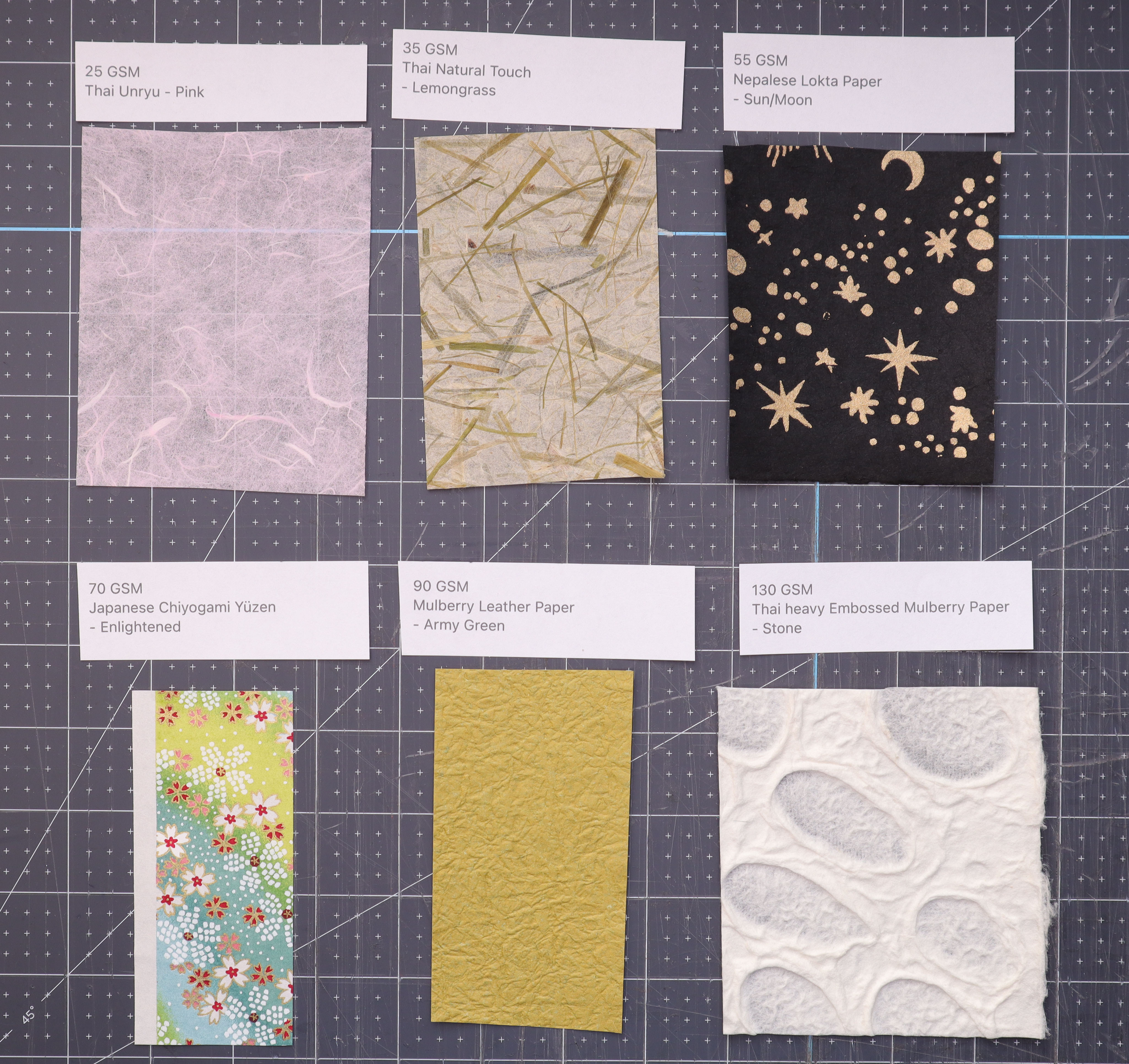

To get started, I chose (6) papers of varying thickness (measured in gsm) from my own personal inventory (listed in the table below).

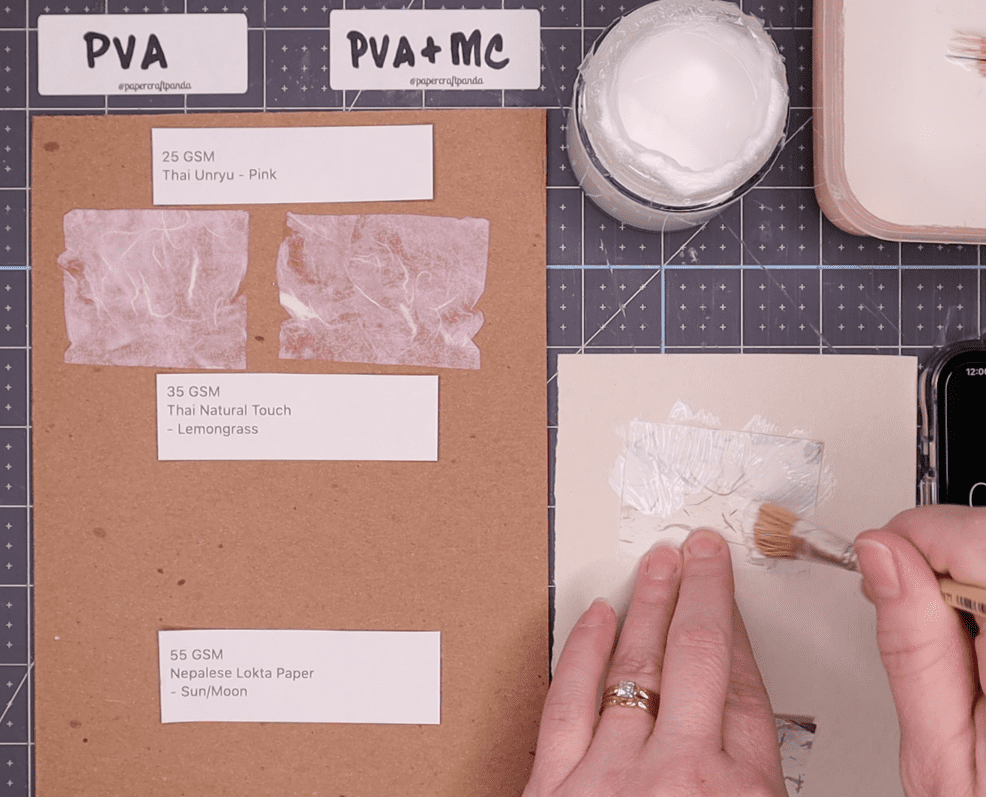

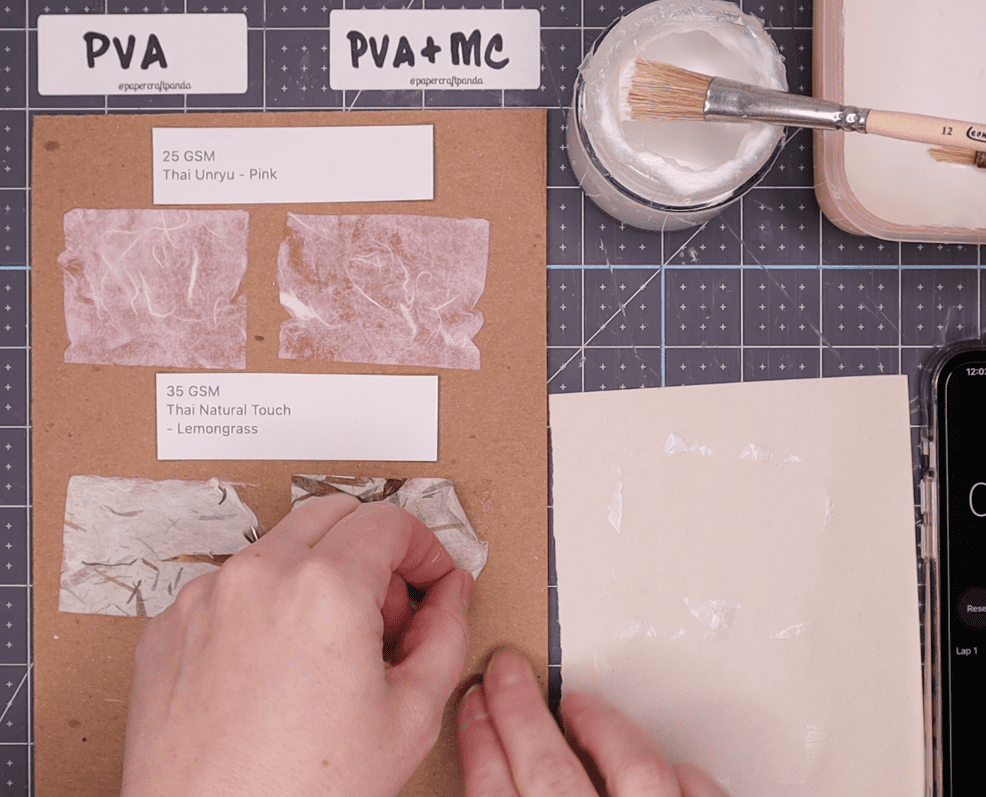

- Each sheet was cut into two strips.

- Standard PVA was applied to the first using a boar bristle brush and ease of application was rated.

- Next, I glued the strip down to the sheet of binder’s board and waited for 20 seconds.

- After 20 seconds, I tried to remove the strip gently with my fingertips and rated the result.

This entire process was repeated with the second strip using a PVA + methyl cellulose blend (60/40).

Key Takeaways

I learned so much from this experiment. Here are my key takeaways:

- Very delicate papers (30 gsm or less) are very sensitive to both adhesives, so proceed with caution and go with whatever works best for you. I personally prefer the PVA/MC blend because it applies smoothly without tearing the tissue.

- Medium weight papers (55-90gsm) work well with both adhesives. This is great, because most cover papers fall into this weight range.

- Heavier papers (130 gsm+) will work with both adhesives, but you’ll need to consider whether or not the paper is highly absorbent and/or laminated. Porous raw materials (like 100% cotton rag or mulberry bark) will work better with thick adhesives that don’t absorb as quickly.

Remember, bookbinding adhesives are up to your preference and should match your approach, materials and style. This experiment was a fun attempt to guide you in the right direction, but the decision is ultimately yours to make!

Enjoy, have fun and – as always – do what works for you!

Video: Best Paper Thicknesses for Standard PVA vs. PVA mixed with Methyl Cellulose

Here is a quick 8 minute video of my tests with voiceover. I love walking you through my thoughts as these tests were being completed. If you like the video, please subscribe and such. Thanks for your support!

I had so much fun running this experiment and hope it was entertaining as well as helpful for you.

More bookbinding goodness

✨ What tools do I need to get started bookbinding?

- Bookbinding Tools & Supplies Quick Start Guide – learn all about book making tools, which to buy first & where to go online

- Pick up my popular Complete Starter Bookbinding Tools Kit – all the bookbinding essentials in one spot

🌟 Looking for a simple way to start making books?

Try a Complete Book Materials Kit. Each one has everything you need (+ tutorials & videos) to make a beautiful book without all the fuss.

Thank you for taking me along on your book making journey!

Misty