As a kid growing up in the United States, I was raised on the Customary Units measuring system. Much like the Imperial system, length is measured in picas, points, inches, foot, yard and mile. I’ve always used this system for bookbinding measurement because I’ve never considered a different way.

After spending several weeks at the American Academy of Bookbinding working only within the metric system, I’ve decided to switch over. It was a surprisingly easy decision. In this post, I’ll explain why it makes more sense (for me) to work in metric than it does in US customary units for bookbinding measurement.

I don’t have to work in fractions

When it comes to length measurement, the US customary units system breaks the inch down into 8ths (1 inch = 8/8). To go smaller than 1/8, we lean on multiples of 8 (1/16, 1/32 and 1/64 – to name a few). It can be a bit confusing.

The metric system works in whole numbers. Working in whole numbers is much easier (unless you’re a mathematician or a little strange (ha)).

There is less room for error

I made a lot of measuring mistakes in my first few years of bookbinding. Due to the nature of fractional computation, I often found myself with too much or not enough area, material or both. It was really frustrating.

With the metric system, I make less errors. I’m not fighting with myself to understand what lies between 1/16 and 1/32 of an inch when my ruler only drops to 1/8. I’ve even used an incra ruler that breaks it all down to 1/128th of an inch or further, but I still found more accuracy (and speed) in metric whole numbers. If you love your incra ruler, by all means, please continue to use it! I have nothing against them. They just don’t work as well for me personally.

Much of the bookbinding world has adopted the metric system

If you love making books and plan to get serious about it, the metric system will become your best friend. Most bookbinding materials are measured in metric or points, both of which have to be converted to US customary units.

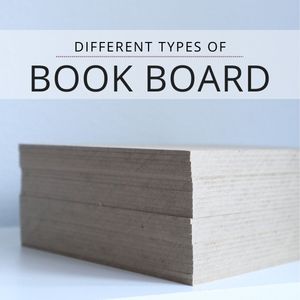

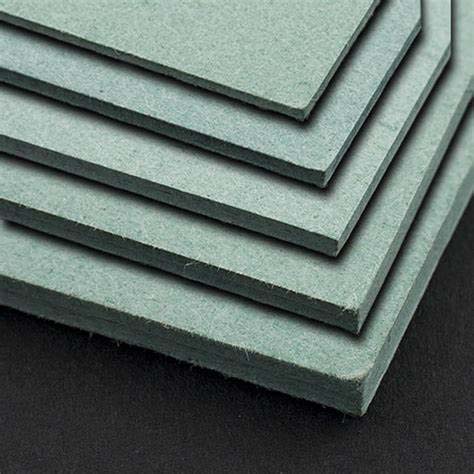

I’ll share two important material examples. First up, book board!

Green millboard (and other types of book board)

Green millboard is a high-density, archival quality, acid and lignin-free millboard used in framing, books, boxes and other areas of binding and conservation.

While the board size is measured in US customary units (inches), the thickness of the board (most important area of measurement) is metric. This type of board is used so often (for so many different purposes) that it comes in five thicknesses to meet demand: 1.1mm, 1.5mm, 1.9mm, 2.3mm and 3.0mm. Yes, it goes all the way up to 3mm thick!

Next, let’s talk about leather!

Leather hides

Herei s an example. Leather hide thickness is measured in mm. Quality hides are usually around 1.0 mm thick. If you convert 1.0 mm to US customary, you’ll get 0.039, which is 39/1000. Yikes.

Here is an example of hide size information provided by J. Hewitt & Sons Ltd., a manufacturer of fine leather used by bookbinders around the world. Notice the focus on metric.

Average Skin Size: 0.74 – 0.84m² (8 – 9ft²)

Approx. Cut Size: 65 x 75cm

Standard Substance: 1.0mm

While the skin size has a reference to square feet, this is only one of the important aspects of buying a hide. It’s more important to understand cut size and substance (thickness). This is especially true when each hide can be hundreds of dollars.

Cut size is the largest possible area you can get with a single cut. From this cut, you could make one or several books (depending on size). I won’t go into further explanation (that’s for another post, another day), but you get the idea.

Here’s an illustration I created to help clarify, just in case.

I’ve been dragged to the watering hole, and I’m drinking

If you’re wondering why this topic warranted its own post, let me explain.

I’ve been making books for the past SIX YEARS using the US customary units system. While it caused me a ton of trouble and woe, I just couldn’t “abandon” my good ol’ US customary units. Maybe it’s because I was raised to adore my country, or maybe I’m just stubborn… either way, I wasted a bunch of time trying to figure out “where I measured incorrectly” on a finished book.

I’m not doing that anymore!

Moving to metric doesn’t mean I’m turning my back on the United States or how I was taught to measure. Heck no. Instead, I’m embracing a new way that works better for the craft of bookbinding.

Yup, I’ve been dragged to the watering hole… and you bet your booty I’m drinking!

Resources

- Check out the American Academy of Bookbinding

- Read my post, 3 Amazing Learnings from My First Visit to the American Academy of Bookbinding

- Make a Quick & Easy Punch Template for 3 Linen Tapes

- Know the Difference | Book Board

Are you new to bookbinding?

Check out my New Bookbinder Guide for helpful information.

Thanks so much for letting me share this with you today. I hope it was entertaining, if not helpful. Now, go follow me on Instagram for the latest news + technical videos I only post on that platform.

ALL my best,

Misty